By Brittany Porter

Brittany is a Senior Associate and the Senior Project Architect for Northlake Commons. Her background ranges from passive house design to specializing in sustainable multifamily and workplace projects. She is passionate about creating low-carbon architecture that promotes health and wellness for all.

As the project architect of Northlake Commons for the past four and a half years, I am excited to celebrate the recent completion of this monumental project. With 168,000 square feet of mass timber structure and 275,000 square feet of total building area, it’s the largest mass timber office building in Washington State at time of completion and likely the largest mass timber lab-ready building in the country. The project is on track for LEED CS Platinum certification.

The mass timber structure amplifies not only the beautiful light-filled interiors and the legacy of development partner, Dunn Lumber, but also the building’s role as a leader in the future of sustainable workplace buildings. Northlake Commons powerfully demonstrates that low-carbon building materials such as mass timber can scale, not just to larger structures, but across a diverse range of project types and markets.

Understanding Carbon

To summarize a complex issue, it’s paramount that the building industry reduce the amount of carbon the built environment releases into the atmosphere and thereby slow the increasing rates of climate change. “Carbon” is shorthand for greenhouse gas emissions (GHGs) and the most significant greenhouse gas is carbon dioxide (CO2). So when we talk about “carbon” we’re really talking about CO2 that is emitted from both the operation of buildings, and from the creation of building materials. The “embodied carbon” of a building material represents the amount of carbon dioxide equivalent (CO2e) that is emitted into the atmosphere during that material’s creation. Cement, steel, and iron are the building materials with the greatest embodied carbon and have at least eight times more embodied carbon than wood products like mass timber.

To meet necessary climate change mitigation targets by 2030 and 2050, the building material industry must decarbonize the manufacturing process of steel, iron, and cement. However, there are significant challenges in decarbonizing these processes and we cannot wait for these innovations to reach industry-wide adoption. This means we need to start reducing the scope of these materials in our buildings and either:

- use recycled steel and concrete,

- design strategies to reduce the scope of these materials, or

- replace the scope with alternate, lower-carbon structural material like mass timber.

Materials Working Together

Northlake Commons contains a double-height warehouse used by Dunn Lumber. To meet the functional needs of this space, a three-story concrete podium design was a necessary part of the structural system. The use of concrete accommodates large-span semi-truck drive aisles, lumber material storage, and industrial-level durability from potential forklift impacts alongside parking for building tenants.

However, more than half of the structural system scope utilizes mass timber. Atop the concrete podium transfer deck stands four stories of office space built with a hybrid mass timber and steel structural system.

This interplay is common. Mass timber buildings are almost always hybrid structures with concrete and steel. The best way to understand the impacts of material scoping decisions is to do a Whole Building Life Cycle Assessment (WBLCA). WBLCAs calculate the combined embodied carbon of all materials and determine how many metric tons of CO2e the project produced through its creation.

The Northlake Commons WBLCA, conducted in 2021 by Glumac and informed by DCI Engineers, studied the building’s structural system and building envelope1. The WBLCA provided meaningful insights into the following carbon-reducing strategies that were implemented:

- a reduced-cement concrete mix,

- a buckling-restrained brace frame (BRBF) lateral system,

- four-stories of mass timber structure, and

- regional mass timber procurement.

Carbon Reduction Strategy #1: Reduced-Cement Mix

Cement is the material in concrete most responsible for carbon emissions. The high heat needed to make cement comes from burning fossil fuels, because there aren’t clean fuel options that can reach such temperatures. Additionally, turning limestone into cement releases CO2 directly into the air due to the chemical reactions involved. This process is why cement production has such a big environmental impact.

The best way to build with concrete, but reduce its embodied carbon, is to use less cement. Concrete mixes can be carefully reviewed and altered to reduce quantities of cement by adjusting water-to-cement ratios and increasing the amount of supplementary cementitious materials (SCMs) in the mix. The revised concrete mix used at Northlake Commons resulted in a carbon benefit of 900 metric tons of CO2e, or an 18% savings when compared to a standard mix.

Carbon Reduction Strategy #2: BRBF Lateral System

The decision to use a buckling-restrained brace frame (BRBF) lateral system in this speculative core and shell building was driven by the need for flexibility in the layouts of future tenant improvements. The alternate option is a concrete shear core, and potentially shear walls, that would divide the floor plate, block views and hamper daylighting. The BRBFs can exist within the office spaces without dividing the space and allow for circulation underneath. The carbon benefit of the BRBF lateral system is 187 metric tons of CO2e avoided, or an 83% savings compared to a concrete shear core system. This data indicates an exciting win-win design solution with both carbon and design benefits.

Carbon Reduction Strategies 3 & 4: Regionally Procured Mass Timber

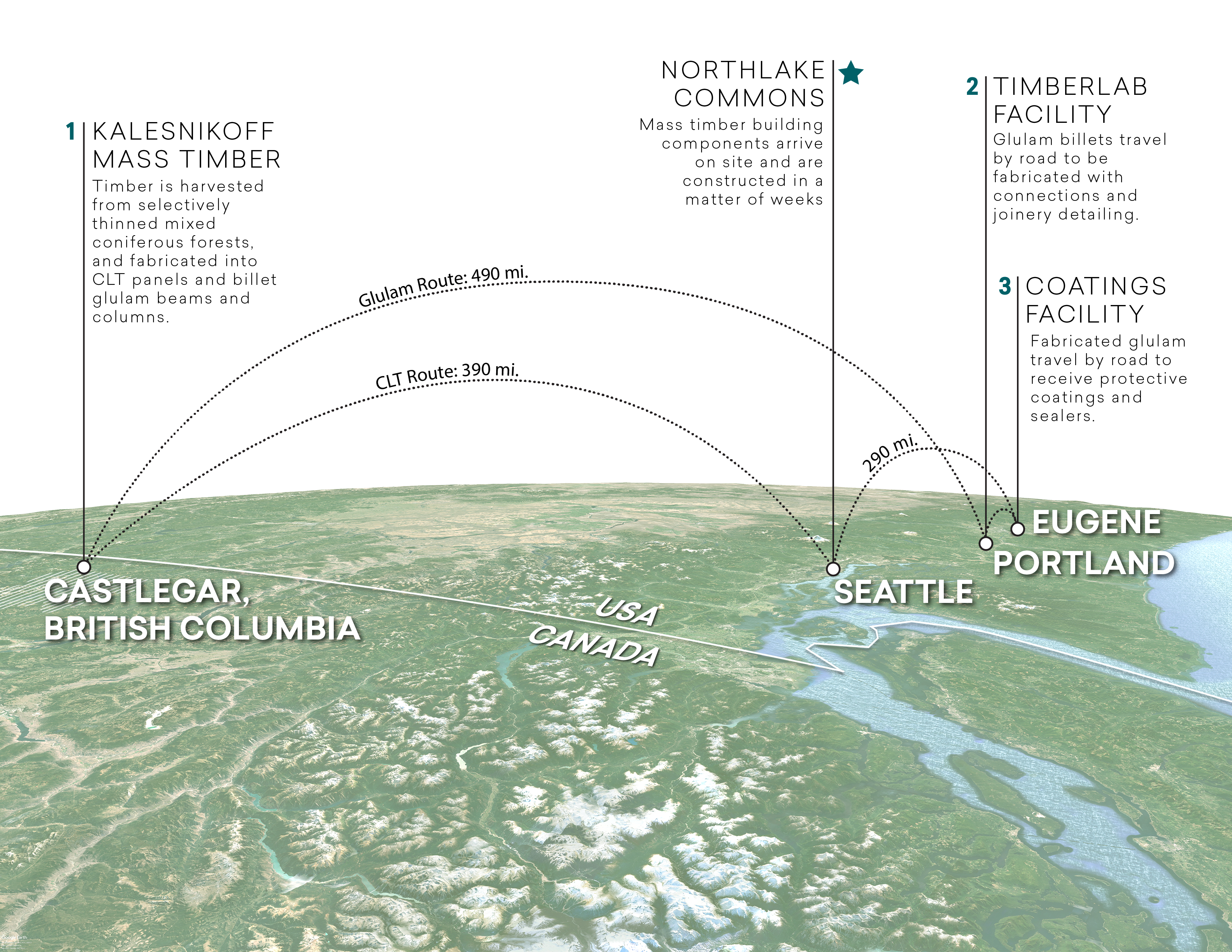

Northlake Commons’ mass timber structure was procured regionally, with cross-laminated timber (CLT) supplied and fabricated by Kalesnikoff in British Columbia and glue-laminated timber columns and beams supplied by Kalesnikoff and fabricated by Timberlab in Portland, Oregon. The wood was harvested from Programme for the Endorsement of Forest Certification (PEFC) certified forests near Castlegar, BC.

The distance materials travel from source to site is reflected in the LCA and impacts overall embodied carbon metrics. Sourcing and fabricating materials for Northlake Commons regionally greatly reduced the project’s carbon footprint. This also enabled the project to quality for the LEED Regional Materials credit, which restricts materials to those found within a 500-mile radius of the site. The LCA calculations show the mass timber structure avoided 2,500 metric tons of CO2e, creating a 23% savings when compared to a concrete structure baseline.2

In total, 2,524 metric tons of CO2e were saved through the design and material choices of Northlake Commons. This is equivalent to powering 500 homes for one year.3

Looking Ahead

One of the key reasons mass timber was viable for Northlake Commons is the Pacific Northwest’s thriving and expanding regional timber supply chain. The Design and Ownership Team also explored using mass timber for a 2015 office building. However, due to an underdeveloped supply chain at the time, it was not possible to secure competitive pricing; the building ultimately utilized a typical steel structural system. It’s encouraging to see so much advancement in recent years and even more potential in the future.

The October 2023 Federal designation of the Pacific Northwest Mass Timber Tech Hub recently put Oregon and Washington at the heart of mass timber innovation. This announcement will lead to opportunities to apply for funding for initiatives that might focus on creating jobs, addressing the housing crisis, improving forest health, and reducing catastrophic wildfires, all centered around mass timber as a building material.

It’s encouraging to imagine what comes next and the projects that might follow Northlake Commons. With continued creativity and collaboration, a future where the building industry’s carbon footprint is cut in half is not only possible, it may also be made of beautiful, healthy, regenerative architecture.